Department

of Chemical Engineering and Materials Science University of California Davis

Drying Water and Ethanol through a Porous Medium!

By

Brett Koehn

For

Professors Powell and Tseregounis

ECH 155: Chemical Engineering Laboratory

Group #1

Ethan

Jensen, Chris Gee, and Zheyu Li

Experiment Performed: January 29, 2016

Report Submitted: February 9, 2016

TABLE

OF CONTENTS:

Abstract……………………………………………………………………………………………3

Introduction………………………………………………………………………………………..3

Theory……………………………………………………………………………………………..5

Experimental

Methods…………………………………………………………………….………7

Figure

1……………………………………………………………………………………8

Results…………………………………………………………………………………………......9

Figure

2…………………………………………………………………………………..11

Figure3………………………………………………………………………………...…11

Discussion……………………………………………………………………………………..…12

Conclusion…………………………………………………………………………………….…14

Nomenclature

Table……………………………………………………………………………...14

References………………………………………………………………………………………..15

Appendix A………………………………………………………………………………………16

Figure

4…………………………………………………………………………………..16

Figure

5…………………………………………………………………………………..17

Figure

6…………………………………………………………………………………..18

Figure

7…………………………………………………………………………………..19

Figure

8…………………………………………………………………………………..20

Figure

9…………………………………………………………………………………..21

Figure

10…………………………………………………………………………………22

Figure

11………………………………………………………………………………....23

Figure

12………………………………………………………………………………....24

Figure

13………………………………………………………………………………....25

Figure

14………………………………………………………………………………....26

Figure

15………………………………………………………………………………....27

Figure

16………………………………………………………………………………....28

Table

1……………………………………………………………………………….......28

Table

2……………………………………………………………………………….......29

Table

3……………………………………………………………………………….......29

Table

4……………………………………………………………………………….......37

Table

5……………………………………………………………………………….......52

Table

6……………………………………………………………………………….......52

Table

7……………………………………………………………………………….......53

Table

8……………………………………………………………………………….......55

Table

9……………………………………………………………………………….......56

Table

10……………………………………………………………………………….....57

Table

11……………………………………………………………………………….....58

Table

12……………………………………………………………………………….....59

Table

13……………………………………………………………………………….....60

Table

14……………………………………………………………………………….....61

Table

15……………………………………………………………………………….....62

Table

16……………………………………………………………………………….....63

Table

17……………………………………………………………………………….....66

Table

19……………………………………………………………………………….....67

Table

20……………………………………………………………………………….....68

Table

21……………………………………………………………………………….....69

Table

22……………………………………………………………………………….....70

Table

23……………………………………………………………………………….....71

Table

24……………………………………………………………………………….....72

Table

25……………………………………………………………………………….....73

Table

26……………………………………………………………………………….....75

Table

27……………………………………………………………………………….....76

Table

28……………………………………………………………………………….....78

Appendix B………………………………………………………………………………............80

Figure

17………………………………………………………………………………....80

Figure

18………………………………………………………………………………....81

Appendix C………………………………………………………………………………............82

Figure

19………………………………………………………………………………....82

Abstract:

This experiment analyzed how the drying of a liquid is

affected by a porous media. Drying in a porous media has four periods which can

be analyzed: The start-up, constant rate, first falling rate, and second

falling rate periods. In order to analyze these periods, we filled up trays of

ethanol and water, and then dried them and measured the loss in mass versus

time. Next we plotted the loss in mass versus time to find a drying rate.

We

then used the mass versus time plot along with an average saturation versus

drying rate plot to find the constant rate periods. We found constant rate

periods for every trial. The drying rate in the constant rate period was used

to find the heat transfer coefficients. The h values were 26.3±3.4, 34.4±4.5,

23.2±3.0, 48.5±6.3, 38.9±5.1, 20.5±2.7, and 8.1±1.1 watts per meters squared

per degree Kelvin, and the htheory

values were 20.4±.61, 20.9±.62, 19.8±.59, 20.9±.63, 20.8±.62, 19.7±.59,

18.9±.57 watts per meters squared per degree Kelvin.

We

also used a plot of loss in mass versus the square root of time to find the

second falling rate. The Keff and Deff values from the second falling rate period were .018±8.2E5 and

.0436±.009 watts per meters per degree Kelvin and .00014±2.6E6 and .000013±3.9E6 centimeters squared per second

respectively. We found that very small beads must be used to examine

the second falling rate.

Introduction:

The

process of drying involves the dynamics of heat and mass transfer. These two

dynamics happen simultaneously during drying. Also, the phases of liquid and

gas are always involved. For special cases, the solid phase can also be involved.

For example, consider a bowl of vegetable soup being heated in a microwave. The

rate at which liquid evaporates from the bowl will be dependent on the solid

vegetables, the soup broth, and the vapor particles above the soup. Drying

dynamics can be studied by analyzing the corresponding phases involved.

Drying undergoes four different periods which are, in

chronological order, the start-up, constant rate, first falling rate and second

falling rate periods. These periods may be seen in the results section where

average saturation is plotted against drying rate. The start-up period is when

the gas-liquid interface and uniform dryer temperatures are reaching

equilibrium. The constant rate period is when the liquid is still above the

porous medium of beads, and therefore drying is controlled by external heat and

mass transfer. The first period falling rate occurs when the partial of

pressure of the liquid is not equal to the vapor pressure at the gas-liquid

interface. This period happens quickly. The second falling rate period is when

the liquid level is so low that the dried vapor must travel through the dry

porous medium.

Drying is an important aspect of many of industrial

processes. In the pharmaceutical industry several different types of dryers are

used to remove moistures or impurities from pure powders.

The

food and dairy industries are dependent on freeze drying, which is a process

that removes or dries the ice of a product that is frozen rapidly.

Understanding

the dynamics of drying allows industries to maximize the efficiency of their

drying processes. According to Carranza, drying can be maximized by using dry

air to influence the concentration gradient across the gas-liquid interface.

Drying will be the quickest if the gas at the liquid-gas interface is

constantly being renewed.

Theory:

Drying through a

porous medium is dependent largely on the two parameters porosity and

saturation. Porosity is

where ε is porosity, Vγ is the volume of the gas in milliliters, Vβ is the volume of the

liquid in milliliters, and VT

is total volume of the tray in milliliters. Saturation is

where S is the average

saturation.

The

complex dynamics of drying behave specifically during the four periods. The

start-up periods, and first falling rate periods are too complex to analyze

quantitatively. Therefore, we only analyzed them qualitatively. The start-up

period is assumed to quasi-steady state. Also, the temperature of the wet

porous medium, Ta is assumed to be less than the drier temperature,  . Furthermore, we assumed that the

gas-liquid interface or simply interfacial temperature, Ti, is equal

to the wet-bulb temperature, which is less than Ta.

. Furthermore, we assumed that the

gas-liquid interface or simply interfacial temperature, Ti, is equal

to the wet-bulb temperature, which is less than Ta.

We

assumed that the constant rate period obeys the equation

because the fluid

evaporates from the wet porous media since the drier is at a higher temperature

than the wet porous media. H is the

heat transfer coefficient in watts per meters squared per degree Kelvin Δhvap is the liquid heat of

vaporization in joules per mole, A is

the area of the gas-liquid interface in meters squared, and dm/dt is the mass drying rate of liquid

in grams per second. The theoretical heat transfer coefficient can be found

through boundary layer analysis,

where kair is the thermal

conductivity of air in watts per meter Kelvin, L is the height of the tray in meters,  is the width of the insulation in meters, Npr is the Prandtl number,

and NRe is the Reynolds

number which is defined as

is the width of the insulation in meters, Npr is the Prandtl number,

and NRe is the Reynolds

number which is defined as

where u is the velocity of flowing air in meters per

second, DH is the

hydraulic diameter in meters, and ν

is the kinematic viscosity of air in meters squared per second.

The Nusselt number is

where

NNu is the nusselt number, havg is the heat transfer coefficient average over the

gas-liquid interface, L is the same

as DH.

The second falling rate has heat

transfer defined by

where

Z is the height of glass beads in the

tray in meters, z(t) is the height of

the liquid level in meters, and Keff

is the effective thermal conductivity in watts per meter per degree Kelvin.

We also know that diffusive

transport dominates diffusive transport because of the quasi-steady state

assumption. Therefore,

where

Naz is the average molar flux

of vapor in moles per meters squared per seconds, c is the liquid concentration in moles per meters cubed, Xea is the mole fraction of evaporated liquid at gas-liquid

interface, Xa is the mole fraction of liquid in the air above the tray, Deff is the effective

diffusivity, and MWA is

the molecular weight of the liquid.

The dry and wet bulb relationship is

described by Bird’s Transport Phenomena

as

where Nsc is the Schmidt number Cpf is the heat

capacity of air, Pavap is the vapor

pressure of liquid, P is the

pressure inside the dryer, and Twb is the

temperature of the wet bulb.

The theoretical

calculation of the diffusivity is

where Dtheory

is diffusivity of water or ethanol in the porous medium in centimeters squared

per seconds, DAB is the

standard diffusivity of water or ethanol.

Experimental Methods:

We began this experiment by coming

in on Thursday January 28, 2016 to prepare a dish containing glass beads and

water. We measured the mass and volume of the tray, the mass of beads, and mass

of liquid. We converted the masses of liquids and beads to volumes. We then

calculated the porosity. This dish had a large diameter and small height.

Furthermore, this dish was suspended in the dryer. This dish was dried

overnight, and a remote computer recorded the data. We set dryer to an air flow

of 3 and let this dish dry overnight.

Figure 1: The drying duct we

used for this experiment. The knobs on the side adjust the airflow and

temperature (the temperature knob was broken). The glass window is where the

water and ethanol sample were inserted and removed.

The following day, we again

calculated the porosity of trays filled with glass beads and liquids by the

same method described in the paragraph above. However, for liquid we used both

water and ethanol. We ran two trials for water, and four trials for ethanol.

For the water trials we used 4 millimeter and 500 micron beads, and these

trials will be referred to as trials 1 and 2 respectively. For the ethanol

trials we used 4 millimeter, 500 micron, 1 millimeter, and 6 millimeters beads,

and these trials will be referred to as trials 3, 4, 5, and 6 respectively. We

wanted to choose a vast array of bead sizes so we would get varying

diffusivities and heat transfer coefficients. The overnight water trial will be

referred to as trial 7. We measured the mass every 10 minutes and 5 minutes for

water and ethanol trials respectively. We removed the trays and weighed them on

a balance, then another group member would record the data in excel. We also

measured the wet and dry bulb temperatures every hour.

We then plotted the mass versus time

and the change in mass over the change in time versus saturation. We then

searched the mass versus time plots (figure 2, 4, 6, 9, 11, 13, and

15) to find a linear fit. We also searched the change in mass over

the change in time versus average saturation plots (figure 3,

5, 7, 10, 12, 14, and 16) to find a flat period.

Using this information we found in these two plots together, we estimated where

the constant rate period was. We then fit this period linearly on the mass

versus time plot to obtain a dm/dt value for the constant rate period. We then

used this fit to find in accordance with equation 3 to find the experimental

heat transfer coefficient h, which is

shown in appendix B. We also found htheory

by performing a boundary layer analysis and solving equation 4, which is also

shown in appendix B. In equation 4 the Reynolds number was calculated inside

the duct, and we looked up the Prandtl number.

We then plotted the mass versus the

square root time. We then examined this plot and the average saturation plot to

estimate the second falling rate. We then linearly fitted the second falling

rate period to obtain another dm/dt value. We then were able calculate Keff from equation 7, which

is shown in appendix B. We were also to calculate Deff from equation 9, and Dtheory form equation 10.

Results:

The constant rate period was

generally similar for all of our trials. For trial 1 (water with 4 millimeter

beads), the drying rate was squirrely, but it oscillated around a rate of 8.78E-4

grams per second. For trial 2 (water with 500 micron beads), the drying rate

was also initially squirrely, but it eventually stabilized to a rate of .001 grams

per second. Trial 3 (ethanol with 4 millimeter beads) had a constant rate

period that lasted nearly the entirety of the trial. This constant rate period

also slowly decreased through the length of the trial. Trial 4 (ethanol with

500 micron beads), had a very quick constant rate period with squirrelly data.

However, the drying rate did oscillate around 0.0038 grams per second. Trial 5

(ethanol with 1 millimeter beads) and Trial 6 (ethanol with 6 millimeter beads)

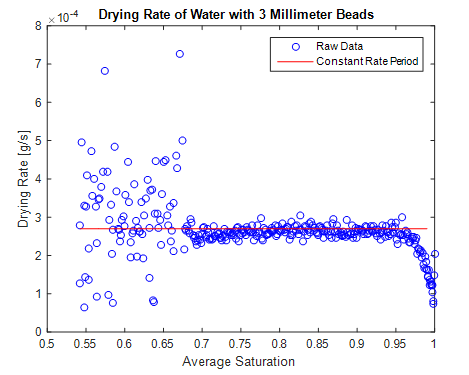

both had a relatively long and stable constant periods. Trial 7 (overnight

water with 3 millimeter beads) initially had a stable constant drying rate, but

it eventually had an oscillating rate.

The second falling rate varied

greatly for each of our trials. The second falling rate was not clear for trial

1. We did not finish this trial, and a second falling rate did seem to be

forming as we approached the end of the trial. However, we did not believe this

drop off in drying rate was conclusive enough, as the drying rate could have

stabilized, and the water sample could have still been in the constant rate

period. The second falling rate was visible for trial 2. This trial showed a

linear fit to the tail end of the mass versus square root of time plot.

Furthermore, the drying rate versus average saturation plot showed a quick and

steady drop off at the end of the trial. The third trial slowly decreased during

the constant rate period, and displayed a miniature second falling rate.

However this was not enough data to analyze. The fourth trial had a second

falling rate which first rose and then fell. The fifth trial had a steadily

decreasing second falling rate. The sixth and seventh trials were not fully

completed, and therefore no second falling rate was observed.

The h values were 26.3±3.4, 34.4±4.5, 23.2±3.0, 48.5±6.3, 38.9±5.1, 20.5±2.7,

and 8.1±1.1 watts per meters squared per degree Kelvin for trials 1 through 7

respectively. The htheory

values were 20.4±.61, 20.9±.62, 19.8±.59, 20.9±.63, 20.8±.62, 19.7±.59, 18.9±.57

watts per meters squared per degree Kelvin for trials 1 through 7 respectively.

The Keff values were .018±8.2E5

and .0436±.009 watts per meters per degree Kelvin for trials 2 and 5

respectively. The Deff

values were .00014±2.6E6 and .000013±3.9E6 centimeters squared per second for trials

2 and 5 respectively. The Dtheory

values were 1.5E-5±9E7 and 9.2E-6±5.5E7 centimeters squared per second for

trials 2 and 5 respectively.

Figure 2: A plot displaying the loss of

mass versus time for ethanol in trial 5. The linear fit of trial 5 for the

constant rate period is shown in red. The fit is close to linear because we

used a large amount of ethanol.

Figure 3: The constant rate curve for

trial 5. The period is close to constant because we used a large amount of

ethanol.

Discussion:

The plots of mass versus time do no display perfectly

linear fits because of error. First off, there was error when measuring the

loss of liquid mass, because the scales could only measure to a tenth of a

gram. Secondly, there was error in the time because the stop watch only

measured to a second. Also, the time measurements were actually estimates

because there was pause between the recording of the measurements of mass and

time. In addition, the constant rate period was estimated by myself, which is a

source of human error. Furthermore, the water plots of mass versus time

(figures 4 and 6) show more linear fits when compared to the ethanol plots

(figures 2,9,11 and 13), because the ethanol trays were removed from the dryer

more often. Therefore, the ethanol samples were cooling for twice as long

outside of dryer when compared to the water samples.

For figures 3, 5, 7, 10, 12, and 14 no perfect constant

rate periods were displayed because of the constraint of having to remove the

trays from the dryer. However, the overnight water tray did display a

semi-constant period when compared to the other trials (figure 16). This

constant rate period was interrupted, because when we began to take

measurements of other tray the next morning, we bumped the tray a large number

of times. This skewed the drying rate of the overnight trial and ruined its

consistency.

The Reynolds number had error in the uinf because the air flow meter only measured to one

hundredth of meters per second, so the percent error was 1 percent. The L measurement because the tape ruler,

because it only measured to a millimeter, so the percent error in length was

negligible.

The

h values have larger values than the theoretical because we were constantly

weighing the tray samples. This caused an influx in disruption, which gave us h

values that were larger than theory. Furthermore, the h values had error in the

temperatures (negligible), area which came from ruler measurements (2 percent

error), and change in mass over time measurements (10 percent error). The htheory had an error of 1

percent from the diameter measurement, 1 percent from the insulation

measurement, and 1 percent from the Reynolds number.

Trials 1 and 3 did not display second falling rates,

instead they display slowly decreasing constant rate periods. This is because

the gaps between the beads were too large, and therefore there was too much

space to inhibit a mass transfer to create a second falling rate. Trials 2 and

5 had small enough beads to inhibit mass transfer, and display a second falling

rate.

The Deff

and Keff

values were calculated from an array of values that occurred over the span

of the second falling rate. This was then averaged and the standard deviation

was taken to be the error. The discrepancy between Deff and Dtheory

comes from several variables containing uncertainties in equations 8 and 9. The

concentration of gas, height of liquid, porosity, dm/dt, partial pressures,

area, Schmidt number, Prandtl number, and temperatures all contain

uncertainties. Furthermore, the Deff

values were much lower because the beads were not packed down, and the gas was

constantly being disrupted when the trays were weighed. The discrepancies

between Keff and Ktheory come from many of

the same uncertainties such as dm/dt, area, temperature, and height of liquid

level.

The error in Dtheory

came from assuming the error in the porosity was six percent, because porosity

is defined by two volume measurements, which is six length measurements. This

is shown in appendix C

Conclusion:

The

values of h and Deff were large when compared to theory, because we were

constantly disrupting the samples by measuring the masses. This would not be a

problem if the dryer could measure the masses of multiple samples at the same

time.

We

were able to obtain constant rate periods for all of the trials because the

constant rate period only depends on external forces of heating. However, we

were not able to obtain second falling rates for all of the trials because we

used beads which were too large. If we want more accurate data of the second

falling rate we need to invest in a new dryer which can weigh multiple trays

over time. We also need to even more trials with even smaller beads.

In

the future, we shall invest in smaller beads up to 1 micron in diameter. This

will allow us to analyze the second falling rate more accurately. Furthermore,

with beads in 1 micron in size, we will also be able to analyze and examine the

first falling rate.

Nomenclature

Table:

Table 2: Trial 7 Data A

References:

1.

Tseregounis,

S., Powell, R., 2016, Drying Porous Media, ECH 155, University of California,

Davis.

2.

Bird,

R., Stewart, W., Lightfoot, E., 1960, Transport

Phenomena, John Wiley & Sons Inc. New York.

3.

Whitaker,

S., 1981, Fundamental Principles of Heat Transfer, R.E. Krieger Publishing

Company, Malabar, Florida

4.

Pharmaceutical Dryers, Pharmacetuctical Machinery, Retrieved

February 2, 2016 from http://www.pharmaceuticalmachinery.in/pharmaceutical_dryer.htm

5.

Freeze Dry Applications, Cuddon Freeze Dry, “ISO 9001 Bureau

Veritas Certification”, Retrieved February 3, 2016 from http://www.cuddonfreezedry.com/applications/

6.

Carranza, J., Heat and Mass Transfer in Drying, Retrieved February 1, 2016 from http://ww.chemicalonline.com/doc/drying-technologies-in-the-chemical-industry0002#liquid

Appendix

A: Raw

Data

Figure 4: A plot displaying the loss of mass versus

time for water in trial 1. The linear fit of trial 1 for the constant rate

period is shown in red. The fit is close to linear because we used a large amount

of water.

Figure 5: The constant rate curve for

trial 1. The period is close to constant because we used a large amount of

water.

Figure 6: A plot displaying the loss of mass versus

time for water in trial 2. The linear fit of trial 2 for the constant rate

period is shown in red. The fit is decently close to linear because we used a

decent amount of water.

Figure 7: The constant rate curve for

trial 2. The period is close to constant because we used a large amount of

water.

Figure 8: A plot of the loss of mass versus square

root of time during the second falling rate for trial 2. The second falling

rate is the linear fit in red.

Figure 9: A plot displaying the loss of mass versus

time for ethanol in trial 3. The linear fit of trial 3 for the constant rate

period is shown in red.

Figure 10: The constant rate curve for

trial 3.

Figure 11: A plot displaying the loss of mass versus

time for ethanol in trial 4. The linear fit of trial 4 for the constant rate

period is shown in red.

Figure 12: The constant rate curve for

trial 4. The period is close to constant because we used a large amount of

ethanol.

Figure 13: A plot displaying the loss of mass versus

time for ethanol in trial 6. The linear fit of trial 6 for the constant rate

period is shown in red. The fit is close to linear because we used a large

amount of ethanol.

Figure 14: The constant rate curve for

trial 6. The period is close to constant because we used a large amount of

ethanol.

Figure 15: A plot displaying the loss of mass versus

time for water in trial 7. The linear fit of trial 7 for the constant rate

period is shown in red. The fit is close to linear because we used a large

amount of water.

Figure 16: The constant rate curve for

trial 7. The period is close to constant because we used a large amount of

water. This was interrupted when we started bumping the tray.

Table 1: Overall Data

Side Length (m)

|

U(inf) [m/s]

|

Kine. visco at 70 deg F [m2/s]

|

NRe

|

0.277

|

0.9

|

1.52E-05

|

16362.46

|

Temperature

|

|||

Time (min)

|

Dry Air (C)

|

Wet Bulb (C)

|

|

0

|

49

|

36

|

|

61

|

48

|

37

|

|

123

|

48.5

|

37

|

|

176

|

49

|

37.5

|

|

283

|

50

|

39

|

|

340

|

49.5

|

38

|

|

367

|

51

|

40

|

|

406

|

50

|

40

|

Table 2: Trial 7 Data A

Tray diameter [cm]

|

Tray height [cm]

|

Water/bead height [cm]

|

11.246

|

7.845

|

1.31

|

Mass of Tray

|

Mass of Tray+Beads

|

Total Mass

|

(g)

|

(g)

|

(g)

|

163.3

|

344.1

|

400.1

|

Table 3: Trial 7 Data B

Comments

Post a Comment