Mass Transfer in Packed Beds

By:

Brett Koehn

Submitted June 5, 2015

Based on experimental work for Laboratory #7,

conducted between May 14, 2015 and March 28, 2015 with group

members

Gary Banh and E.J. Crowley

in Section 5 of ECH 145B

Table

of Contents:

Abstract………………………………………………………………………………………………………………………………………………..3

Introduction…………………………………………………………………………………………………………………………………………....3

Theory…………………………………………………………………………………………………………………………………………………5

Experimental Methods………………………………………………………………………………………………………………………………...7

-Figure

1…………………………………………………………………………………………………………………………………...8

-Figure

2…...………………………………………………………………………………………………………………………………9

Results………………………………………………………………………………………………………………………………………………..11

-Figure

3………………………………………………………………………………………………………………………………….11

-Figure

4………………………………………………………………………………………………………………………………….12

-Figure

5……………………………………………………………………………………………………………………………….…13

-Figure

6……………………………………………………………………………………………………………………….…………14

Discussion……………………………………………………………………………………………………………………………………………15

Design………………………………………………………………………………………………………………………………………………..17

Table

1………………………………………………………………………………………………………………………………...…17

Figure

7…………………………………………………………………………………………………………………………………..18

Conclusion………………………………………………………………………………………………………………………………………...…19

Nomenclature

Table…………………………………………………………………………….……………………………………………………19

-Table

2…………………………………………………………………………………………………………………………………..19

References……………………………………………………………………………………………………………………………………………20

Appendix A……………………………………………………………………………………………………………………………..……………21

Figure

8……………………………………………………………………………………………………………………………..……21

Figure

9………………………………………………………………………………………………………………………………..…22

Figure

10…………………………………………………………………………………………………………………………………23

Figure

11…………………………………………………………………………………………………………………………………24

Figure

12…………………………………………………………………………………………………………………………………25

Figure

13…………………………………………………………………………………………………………………………………26

Figure

14…………………………………………………………………………………………………………………………………27

Table

3…………………………………………………………………………………………………………………………………...28

Table

4…………………………………………………………………………………………………………………………………...28

Table

5…………………………………………………………………………………………………………………………………...29

Table

6………………………………………………………………………………………………………………………………...…36

Appendix B………………………………………………………………………………………………………………………………………..…38

Figure

15…………………………………………………………………………………………………………………………………38

Figure

16…………………………………………………………………………………………………………………………………39

Appendix C………………………………………………………………………………………………………………………………...………...40

Figure

17…………………………………………………………………………………………………………………………………40

Abstract:

During

this lab, we analyzed synthesis gas or ‘syngas’, which is a fuel that can be created with

methane and oxygen. Methane is a greenhouse gas that accounts for 10% of all

greenhouse gas emissions. Therefore reducing methane emissions is good for the

environment. Converting landfill methane emissions into syngas is a useful

process because it produces fuel, stops methane emissions, and only requires

oxygen. However, this reaction requires a catalyst that does not work in the

presence of water. Therefore to create syngas air must be scrubbed of water

moisture. Another solution is to purchase pure oxygen. We found that column

with a packed bed full of Drierite can be used to remove the water moisture. 5 of

these columns were then used to create a design schematic that would cost $420

a year, without initial costs. Purchasing the oxygen would cost $12.8 million a

year. Therefore we should purify air ourselves.

Introduction:

The concepts of mass transfer are

very powerful and useful. One important concept of mass transfer is scrubbing.

Scrubbing is used to purify or filter a stream of multiple components.

Typically the stream being scrubbed contains a desirable and undesirable

component. This stream is run through a column of a third component that

removes the undesirable component from the stream. However, the scrubbing

component eventually becomes ineffective, and needs to be replaced. Therefore,

if we understand the mass transfer concepts of scrubbing, we can also determine

when the scrubbing component needs to be replaced.

One practical use of scrubbing is

eliminating hazardous materials such as methanol, ethanol, isopropanol,

butanol, and acetone from gaseous streams.[1] These hazardous

materials are also water soluble. Therefore, if these materials are released

into the environment, they will contaminate drinking water. In this specific

scrubbing example, a mixture of water and amphiphilic block copolymer is used

to scrub the gaseous streams entering. However, the scrubber does become

ineffective. Therefore, it is very useful to know when the mixture of water and

amphiphilic block copolymer will become ineffective.

Scrubbers

are also used in the creation of high fructose corn syrup.[2] High

fructose corn syrup must be purified of unwanted proteins before processing.

Therefore, high fructose corn syrup is scrubbed with activated carbons and

ion-exchange resins. The syrup will not process correctly and will taste

poorly, if high fructose corn syrup is not purified of these unwanted proteins.

The process of scrubbing streams to separate different components accounts for

40%-70% of both capital and operating costs in the process industry.[3]

During this lab, we examined the mass transfer

between water vapor and solid grains of calcium sulfate. The calcium sulfate was placed inside a

column or packed bed and an air stream saturated with water vapor was allowed

to flow through the packed bed. The grains of calcium sulfate rapidly scrubbed

the water vapor from inflowing the air stream, because calcium sulfate absorbs

atmospheric moisture rapidly.[4] Therefore, the exiting air stream

was very pure oxygen with almost no water vapor left. Removing water from the

air stream is important because water can make reaction catalysts ineffective.

During this lab report, we wanted to create “syngas” which cannot be created in

the presence of water, but requires oxygen as a reactant. Therefore we analyzed

the system of the packed bed to determine the cheapest method of obtaining pure

oxygen. We found that creating oxygen ourselves is much cheaper.

Theory:

The mass transfer concepts that are

involved in this packed bed experiment are very complicated. However, several assumptions

can be made to make this system easier to understand. First off, if the packed

bed is treated as a single slab we know that the gas stream interacts with a, which is the contact area per unit of

packed volume of column. We also know the driving force across a is kc

which has units of length per time. Furthermore, we know that driving force for

the mass transfer coefficient will be defined by the difference of the mole

fraction of water inside the airstream, xw,

and the mole fraction of water at the surface the slab, xws. xws

is approximated to be equal to the concentration at the surface of the packed

bed, Cws, and the

equilibrium absorption constant, Keq,

which has units inversely proportional to concentration. Dimensionless equations

for the depletion of water versus time from the inflowing air stream, equation

1, and the absorption of water at the surface of the slab, equation 2, can now

be solved for

The Reynolds number is defined by

4-ECH 145B, Resources, hammond_j-chem-edu_1935.pdf’

5-Science Lab Evaporators: Amazon.com: Industrial & Scientific. Accessed June 3, 2015.

6-Accessed June 6, 2015. http://www.amazon.com/AMT-5586-Y6-Engine-Driven-1000gpm/dp/B00JBKOYOI/ref=sr_1_1?s=industrial&ie=UTF8&qid=1433550200&sr=1-1.

7-Gavin, Jake. "Oxygen Element Facts." Chemicool. Accessed June 1, 2015.

where X

is the normalized water vapor mole fraction in the air stream is the intial mole fraction of water in the

air stream, Y is the normalized water

vapor mole fraction on the surface of the slab, τ is the dimensionless time, t is the time, seconds, NA is the flux of air coming

in, moles per seconds, ε is the

porosity, C is the total molar

concentration of the air stream, moles per cubic meter,, ξ is the dimensionless length within the slab, z is the length traveled in the slab, meters, and L is the total length of the slab,

meters.

These two equations can be solved

with a finite difference approximation to find the best solution for β. This was done by creating a running

approximate α and β values into a finite difference

scheme. This scheme then gave values for approximated values for X and Y. X was plotted against τ

which gave a clear representation of the break through curve. Y was also plotted against ξ which gave a representation of how

much water was being scrubbed out by Drierite.

The best fitted values of α and β were then used found by evaluating the

solution graphically. β and

α were then used to calculate the Reynolds number and the Sherwood number.The Reynolds number is defined by

where

ρ is density, kilograms per cubic

meters, D is diameter, meters, v is velocity, meters per second, and μ is the kinematic viscosity, Pascal

seconds. The Sherwood number can be assumed to be

where

D is the diffusivity of water vapor,

meters cubed per second, and d is the

diameter of the Drierite grains, meters. There

is also one important relationship which was developed by Gupta and Thodos

between the Sherwood number and the Reynolds numbers which is

where

Sc is Schmidt number.

Experimental

Methods:

This lab was begun by weighing

approximately 5 grams of Calcium Sulfate, which is commercially sold as

Drierite. This Drierite was then placed inside of the slab or packed bed as

shown in figure 2 below. The packed bed was then filled with glass wool at the

entrance and exit of the column. Cooling water was then allowed to flow through

the outer shell of the packed bed to create a counter current heat exchanger.

However, cooling water was only used for half of the trials. Next the wet air

was allowed to flow through the glass wool and Drierite which were both inside the

shell of the packed bed. The Drierite removed the moisture from the wet air,

which allowed dry air to flow out the end of the packed bed. Thermocouples were

then placed on the bottom and top of the packed bed. These thermocouples

measured the temperatures of the dry air coming out and the wet air coming in.

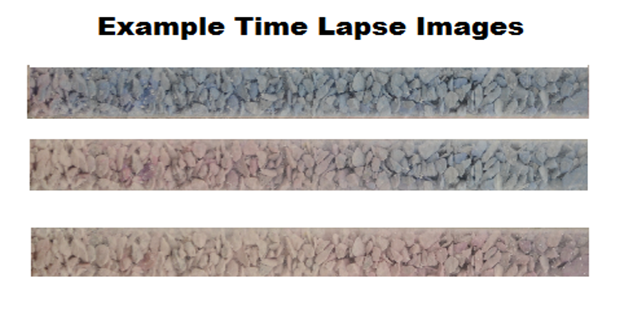

Once the packed bed was set up with wet air flowing through it, we started taking

pictures of the packed bed. We were able to take pictures of the packed bed by

using the automated camera program. The lens of the camera was also position

horizontally in order to make the data analysis easier. Figure 1 shows some

experimental photos that we took at the beginning middle and end of our

experiment.

Figure 1: This

figure above shows the progression of Drierite absorbing water moisture for

Trial 3. The top picture was taken at a time of 40 seconds. The middle picture

was taken at a time of 455 seconds. The third picture was taken at a time of

1025 seconds.

We used flow rates of 12.944 liters

per second, 11218 liters per seconds, 5000 liters per seconds, and 2000 liters

per seconds for trials 1, 2, 3, and 4 respectively. Trials 1 and 4 were

performed without cooling water. Trials 2 and 3 were performed with cooling

water.

Figure 2: This

figure above shows a detailed sketch of the packed bed full of Drierite. Wet

air comes in through the bottom of the column, and dry air comes out the top of

the column. The temperatures at the top and bottom of the column were measured

with thermocouples. Cooling water was also used for half of the trials.

We

then analyzed the pictures of the packed bed by using Matlab. We assumed that

blue and red Drierite corresponded to Y values of 1 and 0 respectively. This allowed us to calculate the Y versus ξ, which was obtained by equation 3d. We

then plotted Y versus ξ for specific

times. We then fit this data numerically by using a finite differences solution

on equations 1 and 2. Finally, we calculated the best fit curves.

ξ was then

calculated for when Y reached values .25 and .75. We then plotted this against τ, which was calculated with equation 3c

and numerically fit this by using a finite differences approach on equations 1

and 2. This approach best fit the data in figures and simultaneously found

values of α

and β. This was done

until the best values of α

and β were found. The temperature of the thermocouples versus

time was calculated and plotted for a cooling and non-cooling trial. The

Reynolds and Sherwood numbers were then calculated with equations 4 and 5

respectively. The Reynolds and Sherwood number was then plotted against the

Reynolds numbers. Theoretical curves were then superimposed over this plot with

data obtained from equation 6.

Results:

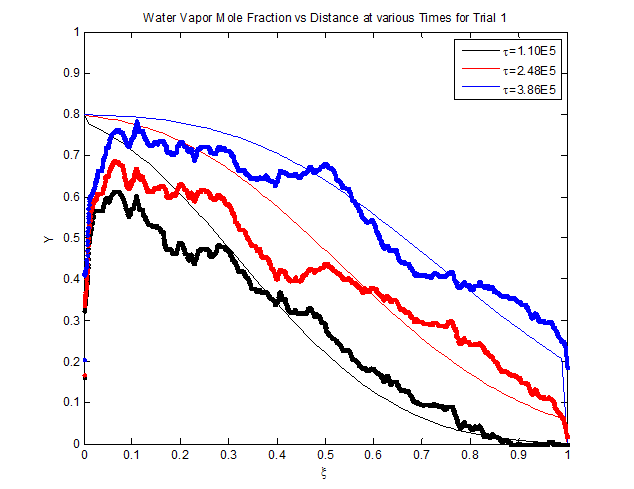

Figure 3: This

figure above shows Y versus ξ. This data was obtained from the

experimental values obtain during trial 1 without cooling.

As

shown figure 3, the variable Y was

plotted versus ξ. These values were

plotted for different τ values. The experimental values of Y decreased as the values of ξ increased for all of the trials that

we analyzed. Furthermore, the numerically fitted data values of Y also decreased as the values of ξ increased. The break through curve is

the section in the best fit lines where the slope initially decreases at an

increasing rate, eventually reached a slope which is completely vertical, and

finally the slope increases at a decreasing rate until the curve is level. This

region of the curve represents the where the Drierite is completely saturated

with water vapors. Therefore, the water moisture is “breaking through” the

packed bed. The experimental data sets also have a break through region. However,

this region is much harder to determine. Therefore, the break through regions

had to be estimated.

Figure 4: This

figure above shows ξ versus τ. This data was obtained from the

experimental values obtain during trial 1 with cooling. The blue data

represents the dimensionless distance for when Y=.25. The red data represents the dimensionless distance for when Y=.75. The error bars are 2 standard

deviations of ξ.

As

shown in figure 4, the variables ξ25

and ξ75 were plotted

against τ. ξ25 and ξ75

were the dimensionless distances when Y

was equal to .25 and .75 respectively. The values of ξ25 increased logarithmically as the experiment preceded

for all of the trials. The values of ξ75

increased exponentially as the experiment preceded for all of the trials. The

experiments had τ values that ranged

from 0 to 3.5E6.

Figure 5: This figure above shows temperature

versus time for trial 1 and trial 2. Trial 1 is the trial without cooling, and

trial 2 was done with cooling.

As

shown in figure 5, the temperatures at the top and bottom of the packed bed

were plotted against dimensional time. The top of the column without cooling had

the highest temperatures, which is represented in figure 5. The temperatures of

the top of the column with cooling water, the bottom of the column with cooling

water, and the bottom of the column without cooling water all had temperatures

of about 24 degrees Celsius throughout the trials. Furthermore,

initially the top of the temperature at the top of the column is less than the

temperature at the bottom of the column for trials 1 and 2. Figure 14 represents

the data from obtained trials 3, which had cooling, and trial 4, which had no

cooling. As shown in figure 14 the temperatures at the bottom of the column

with and without cooling water remain constant at 22 degrees Celsius.

The temperature at top of the column without cooling water was the highest

temperature for the full duration of the trials. The temperature at the bottom

of the column with cooling water was the lowest temperature for the full

duration of the trials.

Figure 6: This

figure above shows the Sherwood number plotted against the Reynolds number. The

error bars are two standard deviations of the Reynolds number and Sherwood

number for horizontal and vertical directions respectively. The experimental

data increases at a logarithmic rate which agrees with the theoretical data.

As

shown in figure 6, the Sherwood number was plotted against the Reynolds number.

These were found from our values of α

and β. α had values of .7±.32, .89±.69,

.80±.56, .20±.17 for trials 1-4. β

had values of 15.3±7.6, 4.21±5.76, 6.5±3.98, and 53±23.4 for trials 1-4. The

values of the Reynolds numbers were 347±3.12, 300±4.62, 133±5.23, and 53.4±2.5

for trials 1-4. The Sherwood numbers were 35.6±29, 33.7±43, 21.9±48.6, and

31.3±23.3.

Discussion:

From figure 3, we know that the

experimental values Y decreases as ξ increases. This is because as water

moisture flows through the Drierite, and the Drierite becomes saturated. Once

the Drierite is saturated, it can no longer absorb water. Therefore as the

dimensionless distance increases in the packed bed, the relative mole fraction

on the surface of the packed bed will eventually be very small compared to the

mole fraction of water flowing in the air stream. The mole fraction in the air

stream will eventually reach zero, and likewise Y eventually reached 0. Therefore, as the time increased during

this experiment, every value of Y became

0. This happened because the packed bed became fully saturated with water after

a certain amount of time has passed during this experiment.

From figure 4, we know that the

experimental values of Y increases as

τ increases. This agrees with figure 3,

because it shows that the packed bed is becoming more saturated with water over

time. Figure 4 also shows that Y approaches 1 at higher values of τ. Furthermore, there are more values of

ξ25 when compared to ξ75. This shows that the mass

transfer decreases with time and distance.

From figure 5, we see that the

reaction between water and Drierite is an exothermic reaction, because the

temperature at the top of the packed bed is much higher without cooling. We

also know that the absorption process takes longer when cooling is not used

because the cooling trials took less time. The mass transfer is more effective

when cooling is used because the Drierite absorbs water the best at low

temperatures. Drierite releases water moisture at high temperatures, which is

bad for the mass transfer between Drierite and water.

The mass transfer coefficient

increases as the flow rate increases. kc

is in units of meters per seconds. Therefore increasing the velocity will

increases the value of kc.

In addition, the mass transfer coefficient will decrease if we were to scale up

this process. As the process gets larger, the value of a get smaller. a gets

smaller because the volume will become much larger compared to the interaction

area.

We used to limiting cases while

performing our experiments. The thing we limited was flow rate. The flow rates

were limited to values of 5 liters per second and 2 liters per second. However,

these flowrate are only valid if the Reynolds number is between 1900 and

10,400. These values are acceptable theoretically. This is represented in

figure 6 as the experimental data agrees with literature values. This is

because the calculated mass transfer coefficients were within the except error

bounds. We also limited our time. The time was limited to 450 seconds.

The error in the mass transfer

coefficient is 2 standard deviations vertically for the Sherwood number and 2

standard deviations for the Reynolds number.

The error bounds for the calculated

mass transfer coefficient α

were .32, .69, .56, and .17 for trials 1-4. β

had error bounds values of 7.6, 5.76, 3.98, 23.4 for trials 1-4. The error in

these results is large because β and α were based on a lot of uncertain

quantities such as the mole fraction of water, length, time, flow rate, and

temperature.

The temperature graph shows us that

this reaction is going to produce a lot of heat if we scale up this backed bed.

Therefore, we need to make sure we have enough cooling water so none of the

equipment is damaged. Furthermore, sufficient cooling is also important for the

reaction to proceed at maximum efficiency because Drierite absorbs more water

at lower temperatures.

Design:

We

need to design a packed bed which can provide enough pure oxygen to react 10

million cubic feet of methane each year and create the valuable fuel, syngas.

This is equal to about 3.3 billion moles of methane. Therefore, we need about

1.65 billion moles of oxygen each year because the reaction requires 1 mole of

oxygen to react with two moles of methane. This is equal to incoming air flow

rate of 14.8 million cubic feet each year or an incoming flow rate of 2.1 cubic

feet per second.

2.1

cubic feet per second is an extremely large incoming flow rate. However, if we

utilize a condenser, such as the industrial evaporator vacuum controller, we

only need an inflow airstream of around 1.35 cubic feet per second.[5]

The engine driven pump that we use meets this flow rate requirement of 1.35

cubic feet per seconds.[6] The flow rate will then enter 4 of the

active columns and eventually react with the methane as pure oxygen. The piping,

tubing, and columns can all be purchased from the same corporation.[7]

The prices of the previously mentioned equipment is shown in table 1.

The

design scheme costs $67,701.11 to produce the required amount of pure oxygen.

However, this price is deceivingly expensive. The initial costs for this design

project are $67,281.11. The annual cost of running this design is only $420 per

year. The annual cost of purchasing oxygen is about $12,800,000. After the

initial year, the design scheme costs approximately 30 thousand times less each

year. Therefore, this scrubber will become more profitable the longer it is

operated.

Figure 7: The

schematic design is shown figure 7. This design requires a pump, a condenser, 5

columns, and a heater. The heater is not shown because the heater is not a part

of the cyclic process this schematic undergoes. There is also cooling water

running counter current through each of the columns.

The design schematic is shown in

figure 7. This design contains 5 columns which will all have cool water running

through them. However, one of these columns is always inactive. The column goes

inactive because there is valve which can be closed below each column.

Therefore, an employee can close the valve below the column. The employee can

then remove the inactive column and extract the saturated Drierite. The

moisture is then removed from the Drierite by a heater. The Drierite is then

placed inside the inactive column. The inactive column is then made active

again by opening the closed valve below the column. The employee will

continuously cycle through each column. Therefore, no wet air is ever allowed

into the reactor.

Conclusion:

We should scrub atmospheric air

ourselves instead of purchasing pure oxygen. Syngas can be created once we have

the pure oxygen and methane from the landfill. Therefore, we can stop methane

emissions from the landfill, and create a valuable fuel. Annual cost of

scrubbing oxygen ourselves is $420. The annual cost of buying pure oxygen is

$12.8 million a year. However, the design will be completely ineffective if

there is not a very efficient condenser and powerful pump. The values we

received for the dimensionless mass transfer coefficients were .7±.32,

.89±.69, .80±.56, .20±.17 for α

and 15.3±7.6,

4.21±5.76, 6.5±3.98, and 53±23.4 for β.

The values we received for the Reynolds number were 347±3.12,

300±4.62, 133±5.23, and 53.4±2.5. The values we

received for the Sherwood number were 35.6±29, 33.7±43,

21.9±48.6, and 31.3±23.3.

Nomenclature Table:

Table

2: Nomenclature Table

References:

1-Jacobs,

John. "Air Pollution Control Technology Fact Sheet." Packed Beds.

2009. Accessed June 4, 2015.

2-Parker,

Ken. Production of Syrup. 2008.

3-Kovel,

Nick. "For Absorption, Desorption, Rectification and Direct Heat

Transfer." In Packed Bed Columns. Vol. 1. Elsevier, 2006.4-ECH 145B, Resources, hammond_j-chem-edu_1935.pdf’

5-Science Lab Evaporators: Amazon.com: Industrial & Scientific. Accessed June 3, 2015.

6-Accessed June 6, 2015. http://www.amazon.com/AMT-5586-Y6-Engine-Driven-1000gpm/dp/B00JBKOYOI/ref=sr_1_1?s=industrial&ie=UTF8&qid=1433550200&sr=1-1.

7-Gavin, Jake. "Oxygen Element Facts." Chemicool. Accessed June 1, 2015.

Appendix A:

Figure 8: This

figure above shows Y versus ξ. This data was obtained from the

experimental values obtain during trial 2 with cooling.

Figure 9: This

figure above shows ξ versus τ. This data was obtained from the

experimental values obtain during trial 2 with cooling. The blue data

represents the dimensionless distance for when Y=.25. The red data represents the dimensionless distance for when Y=.75. The error bars are 2 standard

deviations of ξ.

Figure 10: This

figure above shows Y versus ξ. This data was obtained from the

experimental values obtain during trial 3 with cooling.

Figure 11: This

figure above shows ξ versus τ. This data was obtained from the

experimental values obtain during trial 3 with cooling. The blue data

represents the dimensionless distance for when Y=.25. The red data represents the dimensionless distance for when Y=.75. The error bars are 2 standard

deviations of ξ.

Figure 12: This

figure above shows Y versus ξ. This data was obtained from the

experimental values obtain during trial 4 without cooling.

Figure 13: This

figure above shows ξ versus τ. This data was obtained from the

experimental values obtain during trial 4 without cooling. The blue data

represents the dimensionless distance for when Y=.25. The red data represents the dimensionless distance for when Y=.75. The error bars are 2 standard

deviations of ξ.

Figure 14: This

figure above shows temperature versus time for trial 3 and trial 4. Trial 3 is

the trial with cooling, and trial 4 was done without cooling.

Table 3: Trial 1

Raw Data

Photo

|

Temp C Top

|

Bottom

|

Flow Rate

|

reading

|

mL

|

mass (g)

|

1

|

22

|

25

|

steel

|

100

|

12944

|

10.633

|

2

|

24

|

24

|

||||

3

|

33

|

25

|

||||

4

|

38

|

25

|

||||

5

|

40

|

24

|

||||

6

|

43

|

24

|

||||

7

|

43

|

25

|

||||

8

|

42

|

24

|

||||

9

|

41

|

24

|

||||

10

|

40

|

24

|

||||

11

|

39

|

24

|

||||

12

|

37

|

24

|

||||

13

|

36

|

24

|

||||

14

|

35

|

24

|

||||

15

|

34

|

24

|

||||

16

|

33

|

24

|

Table 4: Trial 2

Raw Data

Photo

|

Temp C Top

|

Bottom

|

Flow Rate

|

reading

|

mL

|

mass (g)

|

1

|

17

|

25

|

steel

|

95

|

11218

|

12.537

|

2

|

17

|

25

|

||||

3

|

25

|

25

|

||||

4

|

28

|

24

|

||||

5

|

28

|

24

|

||||

6

|

28

|

24

|

||||

7

|

27

|

24

|

||||

8

|

26

|

24

|

||||

9

|

25

|

24

|

||||

10

|

24

|

24

|

||||

11

|

24

|

24

|

||||

12

|

23

|

24

|

||||

13

|

23

|

24

|

||||

14

|

23

|

24

|

||||

15

|

22

|

24

|

Table 5: Trial 3

Raw Data

Photo

|

Temp C Top

|

Bottom

|

Flow Rate

|

reading

|

mL

|

mass (g)

|

1

|

22

|

23

|

glass

|

20

|

961

|

5.137

|

2

|

22

|

22

|

steel

|

40

|

4732

|

|

3

|

22

|

22

|

||||

4

|

20

|

22

|

||||

5

|

20

|

22

|

||||

6

|

19

|

22

|

||||

7

|

19

|

20

|

||||

8

|

19

|

22

|

||||

9

|

19

|

22

|

||||

10

|

19

|

22

|

||||

11

|

19

|

22

|

||||

12

|

19

|

22

|

||||

13

|

19

|

22

|

||||

14

|

19

|

22

|

||||

15

|

19

|

22

|

||||

16

|

19

|

22

|

||||

17

|

19

|

22

|

||||

18

|

19

|

22

|

||||

19

|

19

|

22

|

||||

20

|

19

|

22

|

||||

21

|

19

|

22

|

||||

22

|

19

|

22

|

||||

23

|

19

|

22

|

||||

24

|

19

|

22

|

||||

25

|

19

|

22

|

||||

26

|

19

|

22

|

||||

27

|

19

|

22

|

||||

28

|

19

|

22

|

||||

29

|

19

|

22

|

||||

30

|

19

|

22

|

||||

31

|

19

|

22

|

||||

32

|

19

|

22

|

||||

33

|

19

|

22

|

||||

34

|

19

|

22

|

||||

35

|

19

|

22

|

||||

36

|

19

|

22

|

||||

37

|

19

|

22

|

||||

38

|

19

|

22

|

||||

39

|

19

|

22

|

||||

40

|

19

|

22

|

||||

41

|

19

|

22

|

||||

42

|

19

|

22

|

||||

43

|

19

|

22

|

||||

44

|

19

|

22

|

||||

45

|

19

|

22

|

||||

46

|

19

|

22

|

||||

47

|

19

|

22

|

||||

48

|

19

|

22

|

||||

49

|

19

|

22

|

||||

50

|

19

|

22

|

||||

51

|

19

|

22

|

||||

52

|

19

|

22

|

||||

53

|

19

|

22

|

||||

54

|

19

|

22

|

||||

55

|

19

|

22

|

||||

56

|

19

|

22

|

||||

57

|

19

|

22

|

||||

58

|

19

|

22

|

||||

59

|

19

|

22

|

||||

60

|

19

|

22

|

||||

61

|

19

|

22

|

||||

62

|

19

|

22

|

||||

63

|

19

|

22

|

||||

64

|

19

|

22

|

||||

65

|

19

|

22

|

||||

66

|

19

|

22

|

||||

67

|

20

|

22

|

||||

68

|

20

|

22

|

||||

69

|

20

|

22

|

||||

70

|

20

|

22

|

||||

71

|

20

|

22

|

||||

72

|

20

|

22

|

||||

73

|

20

|

22

|

||||

74

|

20

|

22

|

||||

75

|

19

|

22

|

||||

76

|

20

|

22

|

||||

77

|

20

|

22

|

||||

78

|

20

|

22

|

||||

79

|

20

|

22

|

||||

80

|

20

|

22

|

||||

81

|

20

|

22

|

||||

82

|

20

|

22

|

||||

83

|

20

|

22

|

||||

84

|

20

|

22

|

||||

85

|

20

|

22

|

||||

86

|

20

|

22

|

||||

87

|

20

|

22

|

||||

88

|

20

|

22

|

||||

89

|

20

|

22

|

||||

90

|

20

|

22

|

||||

91

|

20

|

22

|

||||

92

|

20

|

22

|

||||

93

|

20

|

22

|

||||

94

|

20

|

22

|

||||

95

|

20

|

22

|

||||

96

|

20

|

22

|

||||

97

|

20

|

22

|

||||

98

|

20

|

22

|

||||

99

|

20

|

22

|

||||

100

|

20

|

22

|

||||

101

|

20

|

22

|

||||

102

|

20

|

22

|

||||

103

|

20

|

22

|

||||

104

|

20

|

22

|

||||

105

|

20

|

22

|

||||

106

|

20

|

22

|

||||

107

|

20

|

22

|

||||

108

|

20

|

22

|

||||

109

|

21

|

22

|

||||

110

|

21

|

22

|

||||

111

|

21

|

22

|

||||

112

|

21

|

22

|

||||

113

|

21

|

22

|

||||

114

|

21

|

22

|

||||

115

|

21

|

22

|

||||

116

|

21

|

22

|

||||

117

|

21

|

22

|

||||

118

|

21

|

22

|

||||

119

|

21

|

22

|

||||

120

|

21

|

22

|

||||

121

|

21

|

22

|

||||

122

|

21

|

22

|

||||

123

|

21

|

22

|

||||

124

|

21

|

22

|

||||

125

|

21

|

22

|

||||

126

|

21

|

22

|

||||

127

|

21

|

22

|

||||

128

|

21

|

22

|

||||

129

|

21

|

22

|

||||

130

|

21

|

22

|

||||

131

|

21

|

22

|

||||

132

|

21

|

22

|

||||

133

|

21

|

22

|

||||

134

|

21

|

22

|

||||

135

|

21

|

22

|

||||

136

|

21

|

22

|

||||

137

|

21

|

22

|

||||

138

|

21

|

22

|

||||

139

|

21

|

22

|

||||

140

|

21

|

22

|

||||

141

|

21

|

22

|

||||

142

|

21

|

22

|

||||

143

|

21

|

22

|

||||

144

|

21

|

22

|

||||

145

|

21

|

22

|

||||

146

|

21

|

22

|

||||

147

|

21

|

22

|

||||

148

|

21

|

22

|

||||

149

|

21

|

22

|

||||

150

|

21

|

22

|

||||

151

|

21

|

22

|

||||

152

|

21

|

22

|

||||

153

|

21

|

22

|

||||

154

|

21

|

22

|

||||

155

|

21

|

22

|

||||

156

|

21

|

22

|

||||

157

|

21

|

22

|

||||

158

|

21

|

22

|

||||

159

|

21

|

22

|

||||

160

|

21

|

22

|

||||

161

|

21

|

22

|

||||

162

|

21

|

22

|

||||

163

|

21

|

22

|

||||

164

|

21

|

22

|

||||

165

|

21

|

22

|

||||

166

|

21

|

22

|

||||

167

|

21

|

22

|

||||

168

|

21

|

22

|

||||

169

|

21

|

22

|

||||

170

|

21

|

22

|

||||

171

|

21

|

22

|

||||

172

|

21

|

22

|

||||

173

|

21

|

22

|

||||

174

|

21

|

22

|

||||

175

|

21

|

22

|

||||

176

|

21

|

22

|

||||

177

|

21

|

22

|

||||

178

|

21

|

22

|

||||

179

|

21

|

22

|

||||

180

|

21

|

22

|

||||

181

|

21

|

22

|

||||

182

|

21

|

22

|

||||

183

|

21

|

22

|

||||

184

|

21

|

22

|

||||

185

|

21

|

22

|

||||

186

|

21

|

22

|

||||

187

|

21

|

22

|

||||

188

|

21

|

22

|

||||

189

|

21

|

22

|

||||

190

|

21

|

22

|

||||

191

|

21

|

22

|

||||

192

|

21

|

22

|

||||

193

|

21

|

22

|

||||

194

|

21

|

22

|

||||

195

|

21

|

22

|

||||

196

|

21

|

22

|

||||

197

|

21

|

22

|

||||

198

|

21

|

22

|

||||

199

|

21

|

22

|

||||

200

|

21

|

22

|

||||

201

|

21

|

22

|

||||

202

|

21

|

22

|

||||

203

|

21

|

22

|

||||

204

|

21

|

22

|

||||

205

|

21

|

22

|

||||

206

|

21

|

22

|

||||

207

|

21

|

22

|

||||

208

|

21

|

22

|

||||

209

|

21

|

22

|

||||

210

|

21

|

22

|

||||

211

|

21

|

22

|

||||

212

|

21

|

22

|

Table 6: Trial 4

Raw Data

mass of Drierite

|

Iteration

|

Temp Lower ©

|

Temp Upper ©

|

7.157

|

1

|

22

|

27

|

2.0 L/min

|

2

|

22

|

27

|

3

|

22

|

27

|

|

4

|

22

|

27

|

|

5

|

22

|

27

|

|

6

|

22

|

27

|

|

7

|

22

|

27

|

|

8

|

22

|

27

|

|

9

|

22

|

28

|

|

10

|

22

|

28

|

|

11

|

22

|

29

|

|

12

|

22

|

30

|

|

13

|

22

|

30

|

|

14

|

22

|

31

|

|

15

|

22

|

32

|

|

16

|

22

|

32

|

|

17

|

22

|

33

|

|

18

|

22

|

33

|

|

19

|

22

|

33

|

|

20

|

22

|

34

|

|

21

|

22

|

34

|

|

22

|

22

|

34

|

|

23

|

22

|

34

|

|

24

|

22

|

35

|

|

25

|

22

|

35

|

|

26

|

22

|

35

|

|

27

|

22

|

35

|

|

28

|

22

|

34

|

|

29

|

22

|

34

|

|

30

|

22

|

34

|

|

31

|

22

|

34

|

|

32

|

22

|

34

|

|

33

|

22

|

34

|

|

34

|

22

|

33

|

|

35

|

22

|

33

|

|

36

|

22

|

33

|

|

37

|

22

|

32

|

|

38

|

22

|

32

|

|

39

|

22

|

32

|

|

40

|

22

|

31

|

|

41

|

22

|

31

|

|

42

|

22

|

31

|

|

43

|

22

|

31

|

|

44

|

22

|

30

|

|

45

|

22

|

30

|

|

46

|

22

|

30

|

|

47

|

22

|

30

|

Comments

Post a Comment